Why choose polyurethane screen panels for mining?

Struggling with frequent screen replacements and unexpected downtime in your mine? This constant maintenance eats into profits and disrupts your entire workflow, causing major operational headaches.

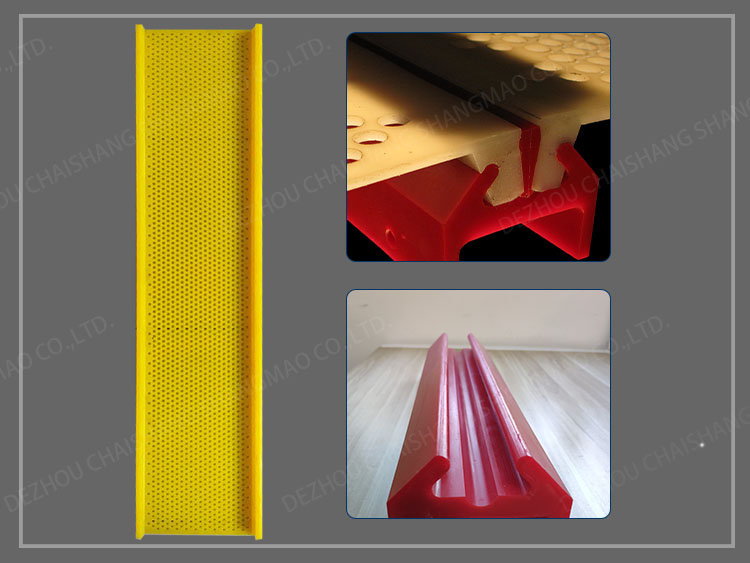

Mining operators choose polyurethane (PU) screen panels for their predictable performance and long wear life. Their anti-clogging design boosts screening efficiency and significantly cuts maintenance downtime, offering a more reliable and cost-effective solution compared to materials like rubber or steel.

But technical specs only tell half the story. I've spent over a decade talking to people who run mines, and their perspective is what truly matters. Let me share what I've learned from my clients, especially those in the tough mining conditions of Australia.

Do mine operators really care about material science?

Are your procurement discussions getting lost in complex material theories? Your team just wants to know one thing: what will keep the plant running smoothly and efficiently.

Honestly, no. In my experience, most operators skip the technical jargon. They ask direct questions: "Which one is easier to use?" and "Which one causes less trouble?" Their focus is purely on operational reliability and reducing maintenance headaches, not on the molecular structure of the material.

This is a conversation I have all the time, and it's most common with my Australian clients. These are people who have seen it all. They are not easily impressed by fancy brochures or complex chemical formulas. Their reality is a world of dust, noise, and tight production schedules that must be met. When they look at a new component, like a screen panel, their evaluation process is brutally simple and practical. They need to know if it will hold up under pressure.

The Core Questions

They boil everything down to two fundamental concerns: performance and hassle. First, will this panel screen material to the correct size efficiently, without constant blinding or pegging? Second, how often will I have to stop everything to fix it or replace it? That's it. Everything else is just noise.

From Theory to Reality

This is where the focus shifts entirely from theoretical advantages to real-world, practical outcomes. A material might be "stronger" or "more advanced" on paper, but if it clogs easily with their specific type of ore and forces a shutdown every week, it's a complete failure in their eyes. They want a solution that works in their specific environment, with their specific material, day in and day out. That's the only test that matters.

How does polyurethane offer more control than rubber?

Does your current screening media feel like a black box? You know it works, but you're never quite sure when it will fail, leaving you unprepared for costly downtime.

While rubber is incredibly tough, its wear pattern can be less predictable, sometimes leading to sudden failures. Polyurethane, on the other hand, offers a more visible and consistent wear life. This allows operators to better forecast maintenance schedules and maintain consistent screening efficiency, giving them greater operational control.

Most of the mine operators I work with in Australia have used both rubber and polyurethane panels at some point. They have direct, firsthand experience with both materials. The general feeling I get from our conversations is that rubber is seen as the steady, durable workhorse. It's incredibly tough and can take a real beating in high-impact applications. But that "steadiness" can sometimes mean a lack of feedback. It works perfectly, right up until the moment it doesn't.

The "Controllable Solution"

This is where they tell me polyurethane is different. Many of them describe it as a "more controllable solution." Because of how it's engineered and the properties of the material itself, you can visually track its performance and wear much more easily.

| Feature | Rubber Screen Panel | Polyurethane Screen Panel |

|---|---|---|

| Wear Feedback | Less visible; can fail suddenly | Gradual, consistent, predictable wear |

| Flexibility | More rigid; can be prone to clogging | Highly elastic; better self-cleaning action |

| Maintenance | Often reactive (replace on failure) | Proactive (plan replacement based on wear) |

This visibility means you are always in the loop. You know how your screens are performing, you can see how they are wearing, and you can accurately predict when they will need attention. You are in control of your maintenance schedule, not the other way around.

Why is predictability the most important factor in mining?

Are unexpected equipment failures constantly derailing your production targets? These surprises are costly, not just in parts, but in lost time, labor, and overall plant efficiency.

In mining, predictability is everything. A client once told me, "I don't want surprises." Unplanned downtime is the biggest enemy of profitability. Choosing components that offer consistent, forecastable performance allows managers to plan maintenance, manage inventory, and maintain a stable production flow.

After being in this business for 11 years, I've realized something crucial. My Australian clients don't choose polyurethane because it's some "high-tech" or "advanced" material. They choose it for a much more practical and powerful reason: it makes their equipment's performance predictable. That single quote from a client—"I don’t want surprises"—perfectly sums up the entire mindset of a successful, modern mining operation. Everything is built around maintaining a steady, predictable flow of material.

The True Cost of a "Surprise"

An unexpected screen failure isn't a small problem; it's a catastrophic event for the production schedule. A single surprise failure means:

- Emergency Shutdown: The entire processing line comes to a grinding halt.

- Lost Production: Every single minute of that downtime is lost tonnage and lost revenue.

- Labor Redeployment: Maintenance crews have to drop their planned, preventative tasks to put out this fire.

- Potential Downstream Damage: A blown-out screen can send oversized material downstream, potentially damaging crushers or conveyors.

Predictability transforms maintenance from a reactive, chaotic fire-fight into a proactive, scheduled, and controlled activity. That stability is worth more than any small difference in upfront component cost.

Isn't polyurethane just more expensive upfront?

Are you worried that switching to a new material will blow your budget? The initial price tag can be deceiving, often hiding the true long-term costs of your current setup.

While polyurethane can have a higher initial purchase price than some alternatives, its total cost of ownership is significantly lower. Its extended wear life, reduced maintenance needs, and improved screening efficiency lead to substantial long-term savings and a higher return on investment.

This is a fair question, and it's one that naturally comes up when procurement managers are looking at quotes. Yes, on a per-panel basis, a high-quality polyurethane panel can sometimes cost more than a traditional rubber or steel wire panel. But I've learned from my most successful clients that they don't just look at the purchase price. They look at the Total Cost of Ownership (TCO). From my 11 years of experience, this is where polyurethane doesn't just compete; it wins.

Calculating the True Cost

To understand the real value, you have to break down what goes into the TCO of a screen panel over its entire life:

- Purchase Price: The initial invoice cost of the panel.

- Installation Labor: The cost of the crew's time to stop production and perform the change-out.

- Downtime Cost: The huge cost of lost production every time you stop the plant to change a screen.

- Frequency of Replacement: How many times you have to repeat this entire costly cycle in a year.

When you factor in that a single PU panel can last three to eight times longer than other media, the math becomes very clear. You are saving massively on replacement parts, labor hours, and most importantly, priceless production uptime. The initial investment pays for itself many times over.

Conclusion

Ultimately, choosing polyurethane isn't about advanced tech. It’s about gaining control and eliminating costly surprises, making your entire mining operation more reliable and profitable.